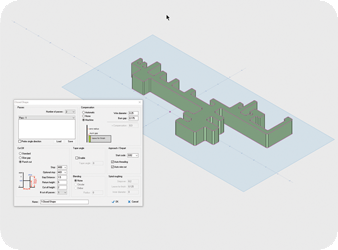

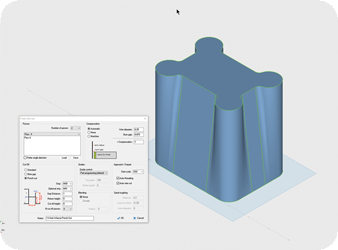

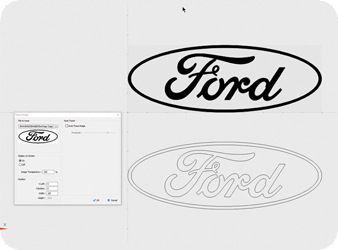

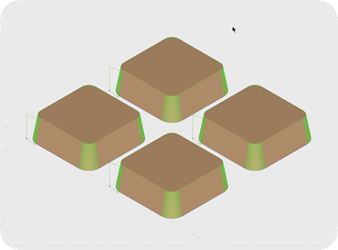

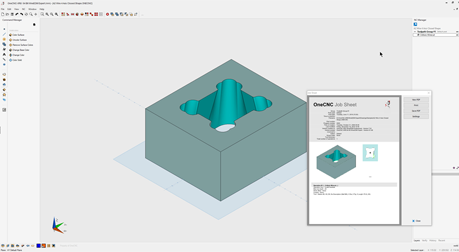

From 2- and 4-axis cutting to easy syncing and complete tab control, OneCNC wire delivers the tools for fast, efficient wire programming.

Designed for simplicity OneCNC Wire will save you time on programming and reduce the opportunity for mistakes. Rough and multiple skim passes are no problem including multiple parts internal or external with automated plug cut off control.